Titan Enterprises and RWC partner on breakthrough dispense solution

Titan Enterprises and RWC have worked together to deliver a streamlined, state-of-the-art single unit for beer dispensing systems by fully integrating Titan's turbine flow technology within RWC's pioneering PolarClean connector.

11th June 2025

FUJI TEKKO unifies motion, I/O and information communication using CC-Link IE TSN

Winding is a key process in a range of industries from food and beverage, agriculture and electrical engineering to automotive manufacturing, construction and consumer goods. It enables the production of products as diverse as the safety film in your car windscreen and the battery in your mobile phone. The continual development of this mission critical process has been the guiding principle of Japan's FUJI TEKKO since its foundation in 1954, explains John Browett, general manager of the CC-Link Partner Association Europe.

11th June 2025

Repackaging delicate items simply and safely

When A + F Automation und Fordertechnik faced the challenge of finding a safety solution for its complex Sortpacker packaging system, a solution that would both protect the operator and guarantee efficiency, it turned to Pilz.

6th June 2025

Efficient design of conveyor systems for food packaging

In the food, beverage and packaging industries, space for conveyor systems is limited. A Swedish machine manufacturer uses the advantages of drive technology from NORD DRIVESYSTEMS to realise a compact design with reduced drive variants for chain conveyors.

2nd June 2025

Rab Jazyniec invests in Ishida checkweigher and multihead weigher solutions

Rab Jazyniec, a leading Polish poultry manufacturer, has invested in a new packaging line for frozen kebabs with an Ishida multihead weigher and checkweigher at its heart.

20th May 2025

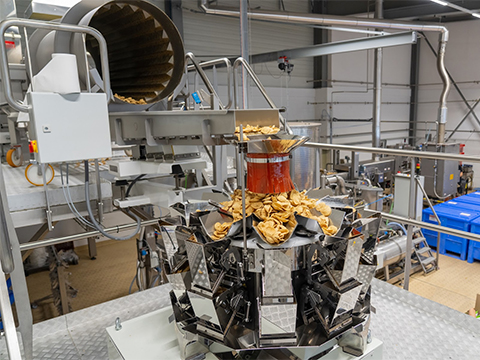

Ishida speed and accuracy delivers packing success for unique crisps

An Ishida multihead weigher is an integral part of a bespoke fully automated packing system for a range of crisps produced by leading Swiss brewery Brauerei Locher from some of the by-products of the brewing process. The system is packing up to 50 bags of crisps per minute in three pack sizes with a maximum overfill of only 1.2g per pack.

7th May 2025

Ishida speed and accuracy delivers packing success for unique crisps

An Ishida multihead weigher is an integral part of a bespoke fully automated packing system for a range of crisps produced by leading Swiss brewery Brauerei Locher from some of the by-products of the brewing process. The system is packing up to 50 bags of crisps per minute in three pack sizes with a maximum overfill of only 1.2g per pack.

28th April 2025

Heat exchangers expand ginger beer production

When Bundaberg Brewed Drinks outgrew its production facility, ensuring the equipment in its new Master Brewery maintained the quality of its famous product, but also ran smoothly was a key priority. A new cooker and thermaliser from HRS Heat Exchangers not only met this brief, but also ensured the processes were as energy efficient as possible.

24th April 2025

New stock management system saves dog food manufacturer £30k per year

RS has helped Butternut Box, the European market leader in fresh dog food, streamline stock management and ensure staff have the right personal protective equipment (PPE) at their fingertips, achieving £30,000 per annum of savings for the firm in the process.

12th March 2025

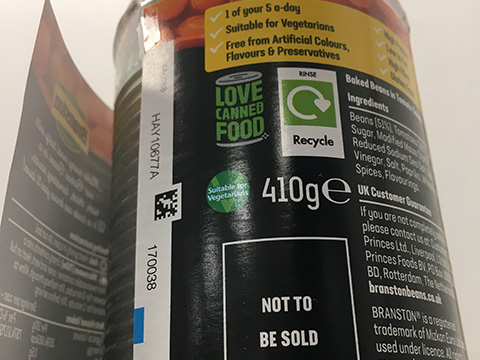

Preventing mis-labelling in food tin production

Identify Direct, trading as Machine Vision Technology, has developed a label-checking system for a major food canning company, which operates 26 production lines over two sites, and used to be particularly susceptible to mis-labelling due the a very large range of products for several major supermarkets.

12th March 2025