New stock management system saves dog food manufacturer £30k per year

RS has helped Butternut Box, the European market leader in fresh dog food, streamline stock management and ensure staff have the right personal protective equipment (PPE) at their fingertips, achieving £30,000 per annum of savings for the firm in the process.

12th March 2025

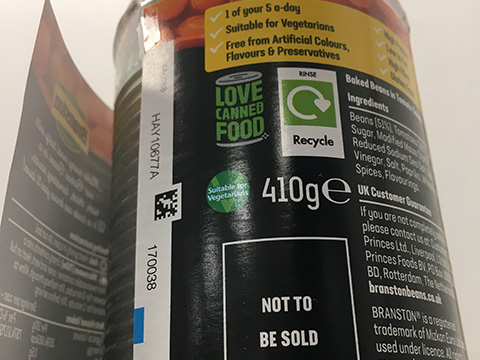

Preventing mis-labelling in food tin production

Identify Direct, trading as Machine Vision Technology, has developed a label-checking system for a major food canning company, which operates 26 production lines over two sites, and used to be particularly susceptible to mis-labelling due the a very large range of products for several major supermarkets.

12th March 2025

Collaborative thermal imaging project enhances fire safety at meat plant

When Dovecote Park, a major food processing plant in Yorkshire, UK, wanted to enhance its levels of fire safety, the company turned to the experience of its long-standing system integration partner WRS Solutions, which in turn engaged with FLIR.

4th March 2025

Processed food manufacturer reduces air compressor lifecycle costs by £200,000 following air audit

A leading supplier of cooked meat products has significantly reduced its air compressor lifecycle costs by upgrading its existing compressed air system which had an external heated dryer to an Atlas Copco oil-free compressor with an integrated heat of compression dryer.

3rd March 2025

Configurable small controller PNOZmulti 2 offers future-proof solution at NOM

In a successful retrofit of a dairy palletising system, the PNOZmulti 2 small controller from Pilz has replaced the obsolete muting solution at Austrian diary industry specialist NOM.

26th February 2025

Fortress supports flour milling firm with daily data

Food safety specialist Fortress Technology has been assisting select Mennel Milling plants in the United States to protect product quality, as well as safeguard its people, processes and productivity.

25th February 2025

High-temperature bearings prove reliable in high-temperature oil application

Hitemp 160 line shaft bearings from Vesconite have demonstrated reliability in a high-temperature vegetable oil pump application.

18th February 2025

Conveyor configuration time reduced by 75% for delicate foods material handling

Vibratory conveyor supplier to the food industry, VCSP, has achieved a step-change in productivity, uptime and hygiene thanks to a new control system from Mitsubishi Electric.

18th February 2025

West-Bake adopts Plex Smart Manufacturing Platform from Rockwell Automation

Rockwell Automation reports that Irish baked-goods company, West-Bake, has adopted the Plex Smart Manufacturing Platform as a company-wide management suite for its growing operations.

12th February 2025

Background Suppression Photoelectric Sensors perfect for cheese Packaging

To increase the capacity of a packaging line for individually packaged cheese portions, a manufacturer required a robust, reliable solution to detect the presence of each cheese portion to control the speed of in-line buffering units. These feed a packaging machine, in a high-volume, hygienic production facility. The company turned to Contrinex for a solution.

6th February 2025