Posted to News on 30th Jun 2023, 12:15

Testing the water with WRAS-approved adhesives

As the demand for safe and reliable products in the food and drink industry continues to rise, ensuring the materials used in the construction of machinery and equipment meets strict standards is of utmost importance, as Bob Orme, senior applications engineer at Henkel, explains.

Adhesives play a vital role in applications in the food and drink sector, providing strength and durability. However, using the wrong adhesive can have disastrous consequences for health, cost and brand reputation. That’s why it is crucial to choose adhesives that are WRAS-approved (Water Regulations Advisory Scheme) for applications that may come into contact with humans, such as food and drink machinery.

WRAS is a trusted conformance mark that certifies that a product complies with the high standards set out by UK water regulations. When it comes to adhesives used in applications where water is involved, it is essential to ensure that no material or substance that causes or is likely to cause water contamination is used. WRAS Material Approval is granted only to materials that have satisfied the requirements of BS 6920:2000 Parts 1 and 2.

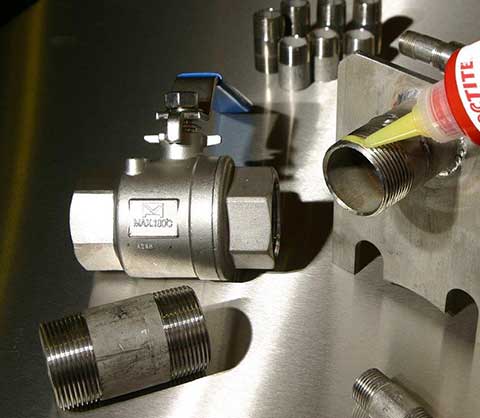

In the food and drink industry, various equipment and machinery can come into contact with water, including pipes, fittings, valves, pumps, taps, showers, washing machines, dishwashers, coffee machines, boilers and toilets. To ensure the safety and integrity of these applications, it is imperative that the adhesives used comply with WRAS standards.

Evaluating non-metallic materials

Non-metallic materials, such as thread-locking adhesives and sealants, are commonly used in domestic water supplies. However, some non-metallic materials can affect the odour, flavour, or colour of water, and they may release soluble organic chemicals or promote the growth of microorganisms. To assess the suitability of these materials, WRAS refers to the tests and criteria outlined in BS 6920:2000. These tests replicate the conditions that materials may encounter during their service life in contact with wholesome water.

WRAS-approved adhesives undergo a rigorous testing process to ensure they meet the highest standards. The tests involve assessing odour and flavour, colour, turbidity, microbial growth and toxicity. Expert panels evaluate the taste and smell of the adhesive compared to tap water. Colour is analysed using a colour spectrum, while turbidity, which measures the transparency of water, is assessed using a turbidimeter. Pass/fail criteria are established for both colour and turbidity.

Microbial testing determines if a product promotes significant growth of aerobic microorganisms. The mean dissolved oxygen difference (MDOD) is used as a criterion over a test duration of 7-10 weeks. As aerobic microorganisms increase, oxygen is removed from the system, and the loss is compared to a control system. The MDOD value, obtained from samples taken at different stages of the test, determines whether the adhesive passes or fails.

Cytotoxicity testing, which lasts for seven days, evaluates whether a product exhibits toxicity to humans. This testing ensures that the adhesive does not pose any health risks when it meets with drinking water.

Avoiding corrosion

Corrosion protection is critical to preventing contamination in drinking water applications. WRAS-approved adhesives now incorporate patented cure chemistry that optimises performance on anti-corrosion, zinc-flake coated fasteners, and passive substrates such as stainless steel and zinc dichromate. Zinc-flake coated fasteners are preferred over zinc-plated and chrome-based alternatives due to their superior resistance to corrosion, safer manufacturing processes and no risk of hydrogen embrittlement.

These adhesives are designed to effectively lock and seal brass fittings in drinking water applications. To ensure the utmost reliability, it is crucial to choose high-quality adhesives. Inferior products may become brittle after the curing process, resulting in broken or fractured seals if the fitting is accidentally dropped or mishandled. A successful adhesive for this application should not only carry the WRAS approval but also possess shock-absorbing properties, provide a durable bond and be supplied without any hazard labels.

Identifying WRAS-approved adhesives

To guarantee the use of WRAS-approved adhesives, it is essential to look for the ‘WRAS Approved’ logo on the packaging. However, it’s important to note that not all approved products may display the logo, as it is not mandatory. To ensure compliance, it is recommended to consult the WRAS approval directory available on their website or reach out to the manufacturer, merchant or retailer for confirmation.

When it comes to applications involving drinking water, compromising on safety is never an option. By selecting adhesives from the LOCTITE range of WRAS-approved thread lockers and sealants, both industry and consumers can be assured of safety and reliability. These adhesives have undergone extensive testing to meet the WRAS standards and have demonstrated their effectiveness in preventing water contamination.