Posted to News on 30th Jan 2024, 11:00

Stainless steel safety interlocks for food manufacturing

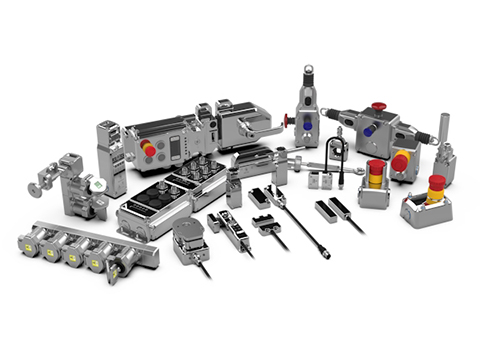

IDEM Safety Switches designs and manufactures the world's largest range of safety products in stainless steel utilising the latest technologies to ensure that the food manufacturing industry never has to compromise on safety over hygiene.

(See IDEM Safety Switches at FoodManufacturing.Live, 1 May 2024, on stand 29)

In the fast-paced food manufacturing industry, choosing the correct safety equipment is paramount. Stainless steel safety interlocks have become essential, offering benefits to workplace safety, hygiene standards and improving overall productivity.

Benefits of IDEM's stainless steel safety switches include:

Corrosion resistance: Stainless steel interlocks withstand moisture, acids, and cleaning agents, ensuring longevity in harsh environments.

Hygienic design: Smooth surfaces and minimal crevices prevent bacterial accumulation, maintaining high hygiene standards and preventing foodborne illnesses.

Durability and longevity: Stainless steel's strength and resistance to degradation ensure interlocks operate optimally, reducing the need for frequent replacements.

High-temperature resistance: Withstanding high temperatures during cleaning and sterilisation, stainless steel interlocks remain effective and reliable under demanding thermal conditions.

For applications that require the guard to be held closed during operation, IDEM has developed the world's smallest RFID locking switch in stainless steel.

The MLZ with flexible actuator and IP69K protection provides versatile operation, with a holding force up to 4000N. This 30mm wide safety interlock is suitable for all physical guard types and utilises OSSD outputs for SIL3, PLe in accordance with the latest international safety standards.

RFID safety switch

IDEM says the MMZ is the first of its kind and the world's smallest RFID safety switch in 316 stainless steel. Tested to IP69K, the MMZ features a mirror polished surface and laser etched markings for complete compliance with hygiene standards.

The symmetrical design means the MMZ can be mounted on either side, supporting both left- and right-hand cable runs. The wrap-around LED ensures complete visibility of the device status from all mounting positions.

Gate switch

The UGB-NET-SS is the world's first network-enabled gate switch suitable for washdown environments. Bring the power of industrial ethernet to your food manufacturing operation, utilising improved device communication, faster installation times and reduced wiring.

The lid is fully customisable, allowing up to six pilot devices to be configured to your specification. The actuator features an RFID sensor for high level coding, reducing the likelihood of external tampering.

Available with either PROFINET PROFIsafe or EtherNet/IP CIP Safety protocols, the UGB-NET-SS is ready to take on your most demanding applications.

In the complex world of food manufacturing, stainless steel safety interlocks offer clear benefits, promoting safety, compliance and efficiency. As the industry evolves, incorporating these interlocks proves to be a strategic investment with short and long-term benefits.

2 Ormside Close,

Hindley Industrial Estate

Hindley Green

WN2 4HR

UNITED KINGDOM

+44 (0)1942 257070