Posted to News on 9th May 2025, 11:00

Ecoplant from Ingersoll Rand delivers dynamic compressor control to reduce downtime and energy costs

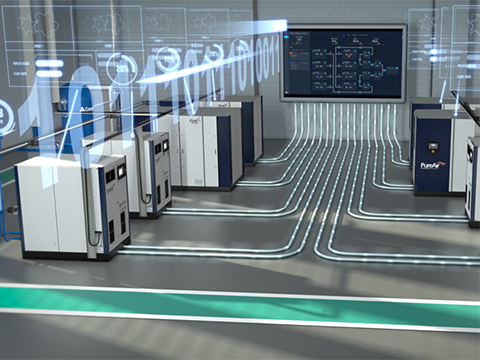

Manufacturing plants can help reduce their downtime and boost their energy efficiency with Ecoplant - the advanced compressor controls platform from Ingersoll Rand.

Using continuous monitoring, Ecoplant adjusts compressed air systems dynamically in response to real-time demand changes. This helps to reduce energy costs and the associated carbon emissions through optimised efficiency, as well as to identify any maintenance concerns that need addressing.

The simple-to-install system is compatible with all compressor technologies and designed for sites with multiple compressors using 300kW and above. It is also available for other manufacturers' models and can be retrofitted to existing compressed air installations.

Ecoplant monitors compressor performance dynamically, providing timely alerts on potential failure risks. As a result, maintenance issues are identified quickly and can often be resolved before they occur - reducing unplanned downtime for improved productivity.

At the same time, Ecoplant ensures pressure levels are stabilised intelligently and that only the necessary amount of electricity is used, helping operators reduce their energy consumption from compressed air generation considerably.

Keith Findlay, Technical Account Manager at Ingersoll Rand, comments: "Intelligent compressed air control has been available to production sites for several years, but Ecoplant is different. Using machine learning, the system monitors 24/7 in real time and adjusts to respond to production changes.

"The savings available with Ecoplant can be considerable. To take the average UK automotive plant as an example, through intelligent efficiency improvements and the reduction in production risk - plus saving time on manual maintenance - the savings can be between 217,000 and 278,000 per year on the installed compressed air estate."

To facilitate smart decision-making on the shop floor, Ecoplant includes a customisable dashboard with real-time analytics and energy insights.

In addition, its cloud-based remote access and unlimited data logging means teams can monitor and manage performance from anywhere in the world - keeping productivity high and maintenance efficient, no matter where they are.

Keith Findlay concludes: "We recognise that capital investment for new plant and equipment can be challenging and generating a fast return on investment is essential. Ecoplant is available as a monthly subscription including all hardware, system installation, and maintenance, so there is no capital outlay and businesses can start realising the cost savings quickly.

"Industry 4.0 is no longer the future of manufacturing - it's the present. The cost and efficiency savings available with Ecoplant offer a compelling solution for manufacturing sites using compressed air today."