FUJI TEKKO unifies motion, I/O and information communication using CC-Link IE TSN

4 days agoWinding is a key process in a range of industries from food and beverage, agriculture and electrical engineering to automotive manufacturing, construction and consumer goods. It enables the production of products as diverse as the safety film in your car windscreen and the battery in your mobile phone. The continual development of this mission critical process has been the guiding principle of Japan's FUJI TEKKO since its foundation in 1954, explains John Browett, general manager of the CC-Link Partner Association Europe.

Next-generation electronic manometer with LED visualisation

1 day agoifm has introduced an electronic manometer with LED visualisation, the PG17xx series, designed to meet the demanding requirements of both hygienic and industrial environments with exceptional performance and reliability.

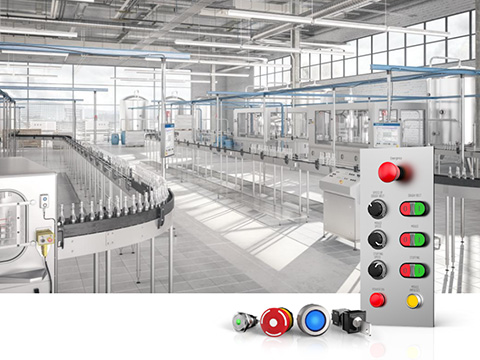

EAO provides high-performance HMI solutions for food and beverage machinery

1 day agoEAO offers advanced HMI solutions designed specifically for the food and beverage manufacturing industry. EAO's broad range of HMI components and systems enables precise, efficient operation and monitoring of automated packaging lines while ensuring maximum safety and reliability.

Fortress launches easy-clean conveyor range

2 days agoFortress Technology overcomes the longstanding industry challenge in food conveyor belt design, helping processors to meet food hygiene demands without compromising on equipment durability.

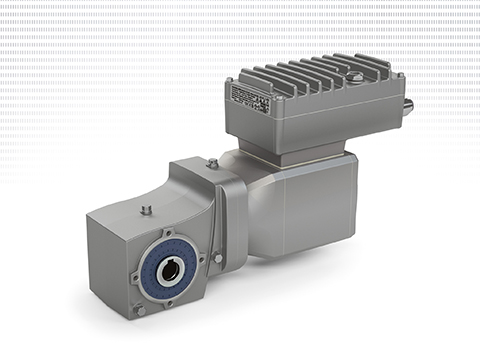

Durable, efficient and easy to clean drive solutions for food and beverage

4 days agoWith its new NXD tupH surface treatment, NORD makes aluminium as resistant as stainless steel, offering the durable, robust and high efficiency drive technology that is the perfect solution in hygiene-sensitive production areas.

A simple guide to checkweighing in food production lines

6 days agoIf you think weighing is just about measuring weight, think again. Frank Borrmann, market manager for the strategic business unit checkweighing and vision, Mettler-Toledo Garvens explores the important role this technology plays in food manufacturing, helping businesses meet weighing regulations, uphold product quality and boost productivity - all while keeping production lines running smoothly.

Embedding smart conveyor design in your bakery

9 days agoFew things are more disruptive to a busy bakery than unplanned downtime. Whether it's a jammed conveyor, a worn-out bearing, or a belt that takes too long to clean, even small interruptions can cascade into lost batches, missed delivery windows and rising costs, as the experts at Regal Rexnord explain.

How product inspection can help compliance with BRCGS global standards

10 days agoIn this joint Q&A, Rob Stevens, Market Manager from Mettler-Toledo Product Inspection and Merce Sanchez, Food Programme Manager, BRCGS offer insights into compliance nuances, the pivotal role of product inspection and actionable strategies to help manufacturers thrive in the face of rigorous standards.

Now published is the MachineBuilding.net Guide to Food & Beverage Industry Machine Design. You can download a free copy here.

Building a positive and smarter food safety culture

548 days agoFortress Technology has published a whitepaper offering practical guidance on how to create a ‘food safety cultural playbook’ that empowers employees and is aligned to the FDA’s New Era of Smarter Food Safety rules and the wider digital transformation journey.

Traceability 4.0: The fundamental element of global manufacturing

919 days agoOmron has produced a whitepaper looking to developments in traceability, highlighting how so called ‘Traceability 4.0’ connects digital and physical technology to optimise and improve yield.

Whitepaper explores traceability in the FMCG sector

939 days agoRecognising how traceability has evolved due to the implementation of technology, Omron has produced a Whitepaper that explores the evolution of traceability and explains why the latest phase, Traceability 4.0, is not just about tracking products throughout the supply chain but also optimising productivity, quality and brand reputation within the manufacturing operation by tying product to process parameters.