Dairy inspection sensitivity gets smarter

5 days agoFood safety specialist Fortress Technology addresses the main metal detection challenges that arise when inspecting dairy applications for contaminants, reviewing how the latest technology is smarter and overcomes a number of sensitivity challenges.

FANUC robot eases palletising bottleneck for salad dressing producer Brunos

9 days agoBy employing a 6-axis industrial FANUC robot to automate the palletising of its bottled salad dressing line, Swiss condiment producer Brunos has alleviated production inefficiencies, allowing the company to keep pace with its growing order book.

Upgrade weighing systems for more efficient and error free production

6 days agoBy implementing smart and adaptable weighing technology in plant machines and equipment, Stephen Hayes, managing director of Beckhoff UK, explains why food manufacturers require control automation to increase efficiency and prevent avoidable costs.

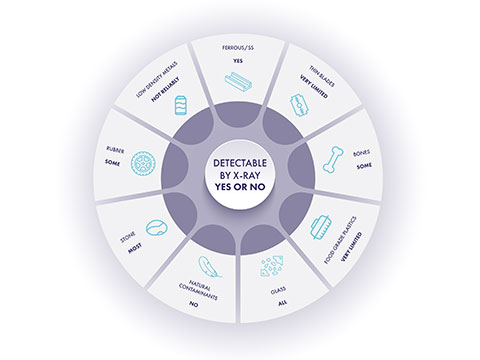

Tips on choosing complementary food inspection technologies

9 days agoCreating a 'best-in-class' contaminant detection strategy requires understanding the respective strengths and limitations of food inspection technologies, as Fortress Technology European sales director Phil Brown explains.

Non-contact point level sensor overcomes media ‘challenges’

10 days agoThe PL240 non-contact point level sensor from Baumer is compact yet robust sensor that can be attached outside plastic or glass tanks (even with a wall thickness of up to 6mm). It can reliably detect point levels of water-based media thanks to compensating adherence.

Dairy inspection sensitivity gets smarter

5 days agoFood safety specialist Fortress Technology addresses the main metal detection challenges that arise when inspecting dairy applications for contaminants, reviewing how the latest technology is smarter and overcomes a number of sensitivity challenges.

Upgrade weighing systems for more efficient and error free production

6 days agoBy implementing smart and adaptable weighing technology in plant machines and equipment, Stephen Hayes, managing director of Beckhoff UK, explains why food manufacturers require control automation to increase efficiency and prevent avoidable costs.

Now published is the MachineBuilding.net Guide to Food & Beverage Industry Machine Design. You can download a free copy here.

Traceability 4.0: The fundamental element of global manufacturing

528 days agoOmron has produced a whitepaper looking to developments in traceability, highlighting how so called ‘Traceability 4.0’ connects digital and physical technology to optimise and improve yield.

Whitepaper explores traceability in the FMCG sector

548 days agoRecognising how traceability has evolved due to the implementation of technology, Omron has produced a Whitepaper that explores the evolution of traceability and explains why the latest phase, Traceability 4.0, is not just about tracking products throughout the supply chain but also optimising productivity, quality and brand reputation within the manufacturing operation by tying product to process parameters.